NewPro Metal Corrosion protection non -adhesive coating for industrial application Na 129

The coating material protects mattfinished and glossy metal surfaces permanently against fingerprints. It increases surface sleekness, reduces soiling and facilitates cleaning. Due to a strong bonding to the surface the coating is highly resistant against chemical and mechanical forces.

Main property: Anti fingerprint – reduces adhesion and visibility of fingerprints. Easy to clean by anti-stick-component. Spray material.

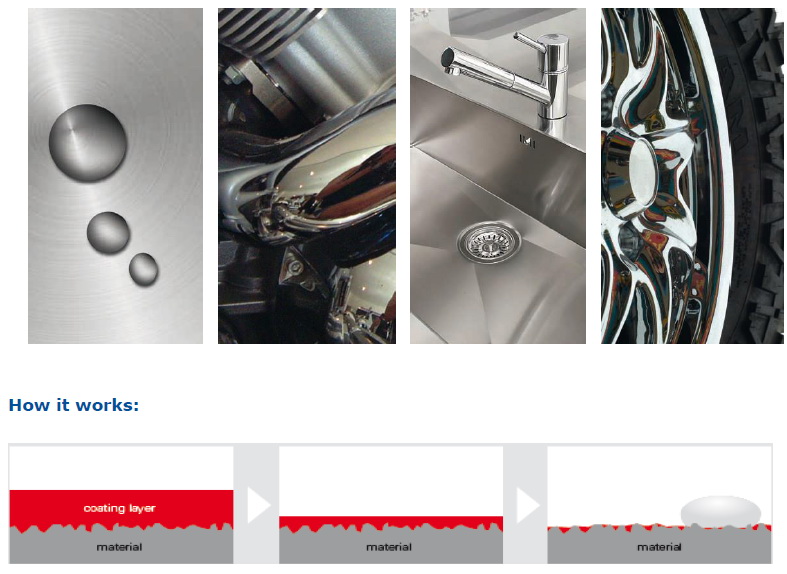

Main field of application: Stainless steel, chrome, aluminium, brass, copper and other metals.

Non-suitable Surfaces: Glass, plastics.

Based on: Solvent-based hybrid matrix.

Colour: Colourless, transparent

Viscosity: 5.76 mPas (rotating viscometer)

Consumption: Approx. 30 g/m2 (sprayed)

Mixing: Use as delivered from original packing.

Available quantities: 5-litre PE canister(3,6kg)

Storage:

Unopened, in original container and at temperatures of 5°C to 35°C(41°F to 95°F) storage is possible for at least 6 months. Protect from frost or tem peratures above 35°C.

Check for signs of deterioration if the recommended storage period has been exceeded.

Seal tightly after opening. Storage must be well ventilated.

Preparation: No preparation necessary – can be applied straight from the container.

Application: Please refer to separate instructions.

Processing temperature:

Air and surface temperature 5°C to 35°C(41°F to 95°F). Curing within 24 hours. Variations in external conditions may affect curing times. Thermal curing at 80°C (176°F) reduces curing time.

Coverage: Approx. 50 ml per m² (spray application).

Safety advice: Please refer to instructions and health & safety advice on the packaging and ensure compliance with relevant industry Health & Safety regulations. For further information see material safety data sheet.

Cleaning of equipment: With alcohol or thinner immediately after application. Potassium hydroxide bath if later.

Retouching and recoating: Remove with standard paint stripper or by sanding down.

Cleaning of coated surfaces: Once cured, surfaces can be cleaned using a mild household detergent.

Disposal: Dispose of any left-over material in accordance with relevant legislation for disposal of paints an solvents.

Technical data:

Salt spray test (EN ISO 9227 NSS):

240 hrs (aluminium), 500 hrs (stainless steel)

Weathering (EN ISO 4892-3: 4h UV-B 60°C; 4h condensation 50°C): 250 hrs

Temperature/humidity cycling (DBL 7906):

15 mins. 23°C;4h -30°C; 15 min 23°C; 4h 80°C; 30 min 40°C 98% humidity)

10 cycles

Chemical resistance: pH 2 to pH 10

Pencil hardness: 4-5H

Taber test (CS10 F wheel; 1000 rotations): 5mg

Temperature resistance: durable up to 200°C (392 F)

Surface energy: 16 mN/m

This technical data sheet has been compiled on the basis of our latest technical knowledge and experience. Considering the wide variety of different surface materials and conditions, it remains the user’s responsibility to determine suitability of the intended application for the specific purpose and to use their judgement and technical expertise in assessing the surface conditions. Since conditions of use are not under the manufacturer’s control, the content of this technical data sheet cannot be taken as acceptance of any liability. Terms & conditions apply.

This data sheet will be superseded by any later versions released. As at 04/09.